Now that the Sustainable Groundwater Management Act (SGMA) has come into effect in some of California’s most overdrawn basins, maintaining accurate water use data is more important than ever. Groundwater Sustainability Agencies (GSAs) will be required to cap and regulate groundwater use in each basin, meaning ag professionals will be responsible for monitoring and reporting water use, including the use of flow meters, telemetry and automation.

Irrigation scheduling is the process used by irrigators to determine the correct frequency and duration of watering crops. It involves understanding, applying, and then monitoring and controlling necessary instruments such as soil moisture sensors, weather stations, rain gauges and flow meters to ensure efficient water use in crop production. This minimizes water waste and supports water conservation while maximizing crop health and yields.

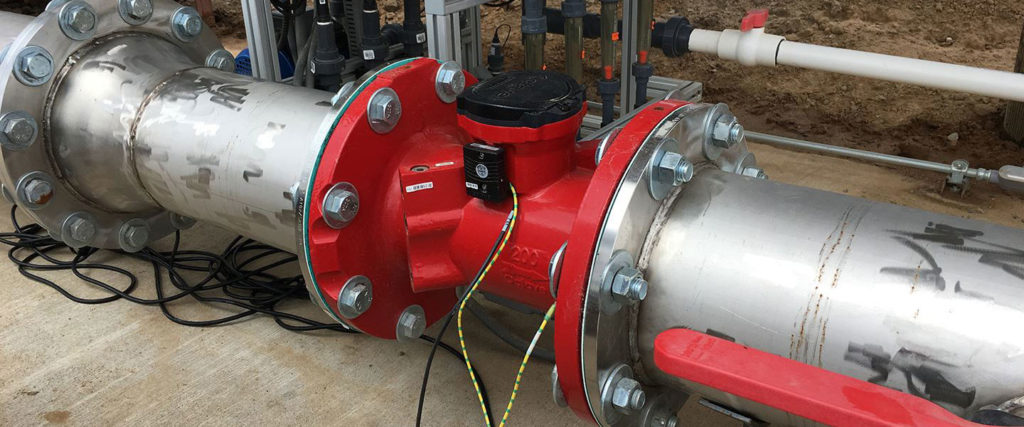

Good irrigation scheduling practices include knowing how much water is applied to each field. A properly selected and installed flow meter accurately measures the amount of water volume applied. An accurate flow meter is an essential tool for practicing good irrigation scheduling and water conservation.

Types of Irrigation Flow Meters

The two most common types of flow meters for irrigation are electromagnetic (mag meters) and propellor (mechanical meters). Propeller meters are mechanical flow meters that have been around in irrigation since as early as 1919, and therefore make up a large portion of the installed base of irrigation water meters.

Over fifteen years ago, many considered propeller meters the best meter choice for irrigation – but that’s not the case today. Costly propeller meter repairs caused many meter users to look for other flow measurement options. With advancements in technology, electromagnetic flow meters are now available with many improvements for operation:

- Simple and highly accurate

- Long battery life

- Battery or external power

- No moving parts, minimal/no maintenance

- Not affected by debris (i.e. dirty water)

- Telemetry ready

- Solar compatible

- Can be installed in tight spaces

With some magnetic flow meters offering a price point similar to mechanical propeller meters, magnetic flow meters have quickly become very popular for use in irrigation.

We recommend using the following four categories to help with proper flow meter selection based on your operation and budget. From the most basic needs to automated data collection for accurate reporting, or integration with other systems and equipment for broader control, monitoring and scheduling, the team at Cal-West Rain can help.

Seametrics Flow Meter

1. How is the application?

Understanding the fluid media, flow range, temperature, pressure, line size, needed signal outputs and available space for installation are all necessary to ensure proper flow meter selection.

What is the media? Is it groundwater, surface water, water from a pond or a lagoon of manure slurry? While a mechanical meter may work fine for a clean water application where the flow range falls within the meter’s capabilities, magnetic flow meters offer the highest accuracy and performance in both clean and dirty water applications. With no moving parts, weeds, trash, and slurries that may otherwise become entangled in a mechanical meter, easily flow through magnetic meters.

What are the minimum and maximum flow ranges? Knowing the minimum and maximum flow range is most critical when selecting a mechanical propeller flow meter. Propeller meters require a minimum amount of flow to turn the bearing assembly and propeller fast enough to ensure an accurate reading. If the flow rate exceeds the rating of the mechanical meter, the bearing assembly can suffer costly damage and the meter will not function properly. With no moving parts to wear out, a magnetic flow meter offers higher accuracy over a broader flow range than mechanical meters.

What is the temperature and pressure? Most flow meters offered for this market are rated up to 150 psi and 140 F operating temperature. Most of these irrigation applications fall well within that temperature and pressure range. However, it’s always wise to confirm the application temperature and pressure.

What is the line size? This will help determine the style of meter. Both electromagnetic and mechanical meters are available in full bore and insertion style configurations. In terms of cost and ease of installation, an insertion style may be the best option for larger line sizes.

Does the meter need a signal output? Some applications require the meter to send a signal such as pulse, 4-20mA or Modbus. In some cases, the output is used to send a signal to a remote telemetry system, allowing irrigators to collect meter data remotely. Signal outputs are optional on propeller flow meters and typically require adding the cost of a transmitter or special digital register that can provide outputs. Most electromagnetic flow meters include a pulse signal output as a standard feature, making them “telemetry system ready,” and Modbus or 4-20mA output signals can be provided for a small additional cost.

Netafim water flow meter

How much room is available to install a meter? Flow meter straight run pipe requirements are expensive in terms of materials and installation labor. In cases where a new flow meter is added to existing equipment, often there is not enough space to accommodate the straight pipe run necessary for accurate flow measurement. Mechanical propeller meters require more space to install due to the longer straight run requirements to ensure proper and accurate performance. Straightening vanes or flow straightening devices can be installed ahead of a propeller meter to shorten the straight run pipe requirement, but can add substantially to the cost and installation labor involved. Typically, a standard full-bore electromagnetic flow meter will fit nicely into a tight space and measure flow accurately. Even some insertion style magnetic flow meters will require less straight run installation space than a propeller meter and operate accurately.

2. How important is accuracy?

In general, electromagnetic meters are more accurate than mechanical meters. Most electromagnetic meters for irrigation, offer +/-1% of flow rate over a wide flow range with no head loss. The most common mechanical meters used in irrigation are propeller flow meters. Propeller meters generally offer +/-2% accuracy within a specified flow range, and some head loss should be expected. Since there are no moving parts to wear out, electromagnetic meters can maintain accuracy over the lifetime of the meter.

3. What is your meter maintenance schedule?

Just like most farm equipment, all irrigation flow meters will need attention at some point.

Mechanical propeller meters have moving parts such as the propeller, bearings and mechanical register that may wear out, causing interruptions in measurement data and resulting in costly repairs. The parts for mechanical meters have increased substantially over the years and repairing one can be almost as costly as replacing it. The standard warranty on most mechanical propeller meters is one year.

Electromagnetic meters do not have any moving parts to break, and maintenance is usually limited to battery replacement. Many battery-powered magnetic flow meters now offer a 5-year battery life, and battery replacement cost is a small fraction of the cost associated with a typical mechanical meter repair. In addition, most electromagnetic flow meters come standard with a two to five-year warranty, depending on the brand.

4. Electromagnetic or mechanical?

Seametrics iMAG 4700P Flow Meter

Electromagnetic flow meters – Also called magnetic meters or mag meters for short, operate by Faraday’s Law – if a conductive fluid, such as irrigation water, goes through a magnetic field, it creates a small voltage. The motion of a conductive fluid through the field generates a small amount of electricity, just like a generator (more flow = more voltage). Electrical coils placed outside the flow are momentarily energized. A magnetic field crosses the flow at right angles, electrodes measure the changing voltage, and the display unit shows rate and total.

Mag meters have been around for 60 years, just not in irrigation. They were typically used in municipal and industrial, water and wastewater applications. In the past 15 years or so, magnetic meter technology has advanced so much that some are now available battery-powered, making them great for irrigation use.

Most mag meters come standard with many features that are optional on mechanical propeller meters. Many times, the overall out-of-pocket cost for a mag meter will be lower than the price of a mechanical propeller meter. To ensure you get the best value for your money, consider what you need in the flow meter – add for pulse output, straightening vanes (for tight space installations), high capacity bearing assembly, digital readout, data logging and any other options you may need to add on the mechanical propeller meter – then compare the price to a battery-powered electromagnetic meter that normally includes all the options you need as standard features.

In the end, mag meters offer higher accuracy over broader flow ranges, no moving parts to replace, durability, no flow obstruction, long battery life, low maintenance, longer warranties, and minimal straight run requirements for tight space installations. In addition to full bore, some mag meters are now available in saddle insertion style for ease of installation in both new installations and retrofit/replacement of existing saddle propeller meters.

McCrometer M0300 Flow Meter

Mechanical propeller meters – Also called propeller meters or prop meters for short, operate under the following principles – The propeller meter consists of a rotating device, typically a helical-shaped impeller, positioned in the flow stream. The impeller’s rotational velocity is directly proportional to the velocity of the flow. As water flows through the pipe, it spins the propeller. The spinning motion is then carried to the head of the meter, through either gears or a drive cable. The instantaneous flow rate and total volume flowed can be read on the mechanical or digital meter register.

Though they operate under the same principle, these meters are available in a variety of installation configurations to suit a range of needs: saddle style, flanged style, threaded ends, grooved ends, etc., which can make installation simpler and less costly. Propeller meters can offer an economical flow metering solution when all that’s needed is mechanical rate and total volume flowed. They typically work fine in clean water applications, but water-carrying debris can restrict or damage the meter’s moving parts. While mechanical propeller meters used to be the most economical choice for irrigation, that’s typically no longer the case when you include the costs of all the necessary options. If you need anything other than mechanical rate and total, making an “apple to apple” comparison of ALL costs (including installation, maintenance, etc.) and benefits of mechanical vs. electromagnetic may be wise before making any purchase decisions.

Selecting and Installing Flow Meters

Whether it’s a mag meter or propeller meter, the Cal-West Rain team of irrigation experts can recommend a meter that helps you achieve your project goals. From the most basic needs to automated data collection for accurate reporting, or integration with other systems and equipment for broader control, monitoring and scheduling, Cal-West Rain can help. Contact your local Cal-West Rain branch today.

We offer a wide range of flow meter brands to meet almost any needs.

- Bermad flow meters

- Krohne flow meters

- McCrometer flow meters

- Netafim flow meters

- Seametrics flow meters

- Water Specialties flow meters

References

https://blog.mccrometer.com/flow-meters-for-agriculture-applications-an-overview/

https://www.mccrometer.com/technical-articles/electromagnetic-and-ultrasonic-meters-comparison

https://www.mccrometer.com/Agricultural-Turf

https://www.mccrometer.com/technical-articles/what-are-flow-meters-and-how-do-they-work

https://blog.bermad.com/irrigation/bermad-water-meters-for-irrigation-data-driven-insights-for-todays-growers

https://www.technoflo.com/products/irrigation

https://www.seametrics.com/blog/4-keys-for-selecting-an-irrigation-flow-meter/

https://www.netafimusa.com/agriculture/products/product-offering/water-meters/