With years of VFD experience, we’ve seen many cases where growers experience costly pump downtime and expensive repairs for not properly protecting their VFD pumps. Conversely, we’ve also seen many cases where downtime and repair costs are avoided through the use of a well-protected VFD panel. With that in mind, this article provides an overview of VFDs and how to properly protect them to avoid costly pump downtime and repairs.

What is a VFD (Variable Frequency Drive)?

Most irrigation systems have variable flow and pressure needs. Variable frequency drives (VFDs) are electric controllers that vary the speed of the pump motor, allowing the pump to respond smoothly and efficiently to fluctuations in flow and/or pressure demand.

From orchards to vineyards and row crops, more and more growers across California are using VFDs to operate all types of irrigation pumps. The benefits of VFDs vary based on the crop, irrigation system, and electric utility serving your location.

- Lower costs through energy and maintenance savings

- Irrigation system flexibility and water conservation with variable speed capabilities

- Ability to easily throttle the VFD to control flow without using valves

- Easily program the drive to maintain certain flows or pressures based on in-field demand

- The cost and size of VFDs have decreased while performance has improved

- Some utilities require VFDs to minimize demand or line disturbance on the electric grid

- Rebates or incentives from electric utilities (i.e. PG&E)

- Longer motor life and less motor maintenance

Are VFDs Limited to Certain Types of Ag Irrigation Pumps?

In our experience across Central California, VFDs are used on all types of irrigation pumps including deep well pumps, lift pumps and booster pumps of all sizes.

- Deep well vertical turbine pumps

- Lift pumps: Transferring water from reservoirs or canals

- Booster pumps: Used to increase the water pressure and/or flow rate

- Typical VFD pump horsepower range: 5 – 1,000 hp

Protecting Your VFDs

VFDs contain sensitive components and circuit boards, much like a computer. Therefore, voltage variation and surges without protective equipment can easily damage the VFD resulting in costly pump downtime and repairs. Replacing a damaged VFD can cost anywhere from $7,500 to $50,000+ depending on its horsepower requirements.

Although all VFDs have circuit breakers, a high percentage of VFDs don’t have additional protection from voltage variation and/or substantial voltage spikes from the power grid or catastrophic events like lightning strikes.

What Additional VFD Protection is Recommended?

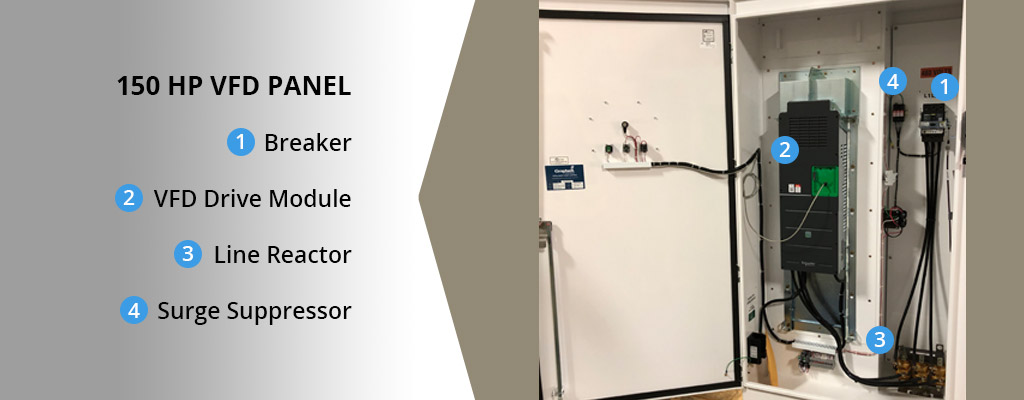

Although circuit breakers provide important protection, including a Line Reactor and a Surge Suppressor as part of your VFD panel is highly recommended.

- Line Reactor (aka Voltage Filter) – High voltage microsecond transients are common in all power grids. A line reactor is an inductor that absorbs high voltage microsecond transients that can damage the VFDs running your pumps. Line reactors achieve this by slowing the rise time of the voltage spike to keep your VFDs safe. Breakers alone do not provide this type of added protection for your VFD.

- Surge Suppressor (aka TVSS) – A Transient Voltage Surge Suppressor (TVSS) is an older industry term which has been replaced in Standards bodies by the term “surge protective device” or SPD. A transient voltage surge suppressor is a device that is installed on your AC power line to act as a cutoff if there is a momentary surge of electrical power, also known as a “transient.” TVSS devices are considered crucial to the protection of sensitive equipment which would result in circuitry damage if power overloads were allowed to pass through to them. With regard to surge protection, TVSS devices or SPDs are by far the most popular forms of VFD damage avoidance available today.

How are Line Reactors and Surge Suppressors added to a VFD?

Cal-West Rain supplies VFD panels that comply with UL508 safety guidelines. In most cases, these panels are custom built by our UL508A certified shop and include the following equipment sized to the customer’s pump.

- Breaker – Schneider or similar

- VFD – Schneider, Yaskawa or similar

- Line Reactor (Voltage Filter) – TCI or MTE

- Surge Suppressor (TVSS) – Phoenix Contact, Raycap Strikesorb or similar

UL508 is the Standard for Safety for Industrial Control Equipment and covers industrial controls and related devices rated 1500 volts or less used for starting, stopping, regulating, controlling, or protecting electric motors.

If you have questions about VFDs (new installs, troubleshooting, repairs, etc.), contact the nearest Cal-West Rain branch. We’re a full-line irrigation and pump company serving the Central Valley and Central Coast of California. With branches in Kerman, Paso Robles, Hanford and Bakersfield, we’ve served the heart of California’s most productive farming region since 1989.

Acknowledgment

We’d like to thank Robert Keith, Industrial Automation Technology Specialist, at Graybar (Central California) for his technical expertise and input on this article. Graybar, a Fortune 500 company, is a leading North American distributor of high-quality components, equipment, and materials serving the industrial and utility markets, along with the construction, commercial, institutional, and government (CIG) markets.